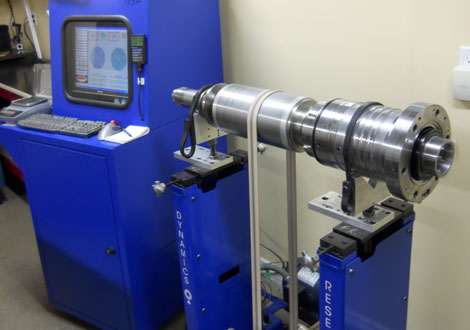

CNC Machine Spindle Balancing // Spindle Services

Spindle balance plays an important role in the lifespan of your machinery. Proper spindle balancing can ensure that your machine is quiet, accurate and achieves good surface finish.

We can balance spindles from 20 pounds with operating speeds up to 60,000 rpm to 1000 pounds with operating speeds up to 5,000 rpm and provide a balance report showing before and after results.

How would spindle balancing benefit me?

There are many reasons why spindle balancing should be integrated into your next rebuild.

Lifespan

Imbalance causes unwanted vibration within the spindle bearings, and can even lead to breakdowns. Spindle balancing prolongs bearing and tooling life.

Noise Level

Spindles that are out of balance are noisy. Spindle balancing reduces the amount of noise produced by each machine, producing a more comfortable work environment.

Accuracy

It is well known that the most accurate machines need an exceedingly high level of spindle balance. However, even slower RPM machines can benefit from this process, affording you a higher level of reliability and consistency.

Finish

Good surface finish is dependent on spindle balancing; an unbalanced machine will result in a very uneven finish.

Specialized Spindle Services uses a 2-plane dynamic balancing machine, ensuring that your spindle rebuild will give you years of trouble free service.

Contact Specialized Spindle Services for a Quote for Machine Spindle Balancing

We disassemble and quote for free!

Call: 519-662-2250

Spindle Services

Other

Services

Examination and Removal, Spindle vibration analysis, Drawbar force testing, Servo Motor Rebuild and more.

more info >>

Get a

Quote

Call Specialized Spindle Services

for a free Quote!

519-662-2250

Brand Expertise

AXXIOM - BRIDGEPORT - BROTHER - BROWN & SHARPE - BRYANT - BULLARD - CAMPBELL - CANTON - CARLTON - CARVER - CHEVALIER - CHINO - CHIRON - CHURCHILL - CINCINNATI - CINEX - CLEERMAN - COLCHESTER - DAEWOO - DECKEL - DOOSAN - EXCELLO - FADAL - FAEMAT - FAG - FANUC - FELLOWS - FIRST - GAMFIOR - GILDEMEISTER - GILMAN - GMN - HAAS - HAMAL - HARDINGE - HESSAPP - HITACHI - HITACHI SEIKI - HSD - HURCO - HYDROMAT - HYUNDAI - IBAG - IKEGAI - IMT - JONES & LAMSON - JOHNFORD - JONES & SHIPMAN - KESSLER - KIA - KINGSBURY - KITAGAWA - KITAKO - KITAMURA - KIWA - KURAKI - LEADWELL - MAHO - MAKINO - MATSUURA - MAZAK - MITSU-SEIKI - MITSUBISHI - MITSUI - MIYANO - MONARCH - MOORE - MORI SEIKI - MYFORD - MYL - NAKAMURA - NAKAMURA TOME - NEO - NIGATA - NSK - OKAMOTO - OKK - OKUMA - OKUMA HOWA - OVERBECK - PARKER MAJESTIC - PERSKE - POPE - PRECISE - PUMA - RENAUD - SAMSUNG - SKF - SNK - SPINTEC - STANKO - TAKUMI - TOS-HOSTIVAR - TOSHIBA - TOYO KOGYO - TOYODA - VTEC - WADKIN - WAGNER - WALTER - WASINO - WEISS - WEISSER - YANG - YASKAWA

contact sss >>Super Precision Bearings

We have the expertise to ensure the correct bearings are installed in your spindle. We can also recommend more appropriate bearings to suit your specific needs and give you optimal spindle performance.

We only install bearings in our state of the art clean room facility to avoid contamination.

We have OEM accounts with all the major bearing manufacturers so we can offer competitive prices for all your bearing needs including ceramic.

Our suppliers include:

NSK, NTN, FAG, BARDEN, SKF, SNFA, FAFNIR, TIMKEN, GMN

Our expertise includes the following types of bearings:

- Angular contact ball bearings.

- Reduced O.D. angular contact ball bearings.

- Hybrid ceramic angular contact ball bearings.

- Straight and tapered cylindrical roller bearings.

- Angular contact thrust bearings.

- Ball screw support bearings.

- Taper roller bearings.

- Precision deep groove ball bearings.

Call Today for a Quote!

Specialized Spindle Services is centrally located in southern Ontario, Canada, and can offer fast turnaround to reduce your downtime.

contact sssSpecialized Spindle Services

Our extensive experience covers the repair and rebuild of most makes, models and applications of CNC spindles including mill, lathe, grinder and router spindles for the metal, wood, glass, plastic granite and graphite industries. A large proportion of our workmanship is rebuilding and repairing spindles from CNC Machines.

Our trade certified staff, who's combined knowledge of bearings, drawbars and spindle configurations allows us to rebuild your spindle for optimum performance and reliability.

There are significant financial savings having Specialized Spindle Services rebuild your spindle compared to an OEM (original equipment manufacturers) rebuild. Most replacement spindles from OEM's are rebuilt from a different customer's spindle which is why they require your spindle back in lieu of a core charge.